Knitting

Where Innovation Meets Tradition

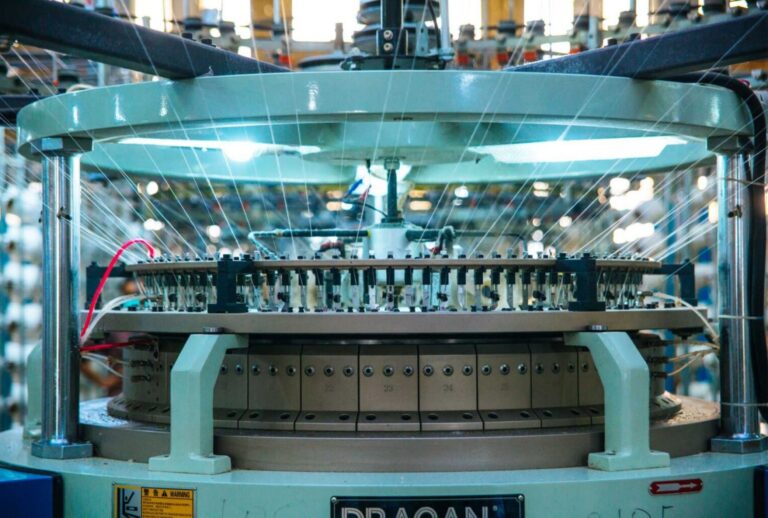

At W. Brothers Apparel, knitting is more than a manufacturing step—it’s the heart of our craftsmanship. We transform approximately 25 metric tons of yarn into premium knitwear every day. This scale reflects not just our operational efficiency but our dedication to meeting global demand without compromising on quality.

Our knitting facility is equipped with state-of-the-art machinery, including advanced circular knitting machines and computerized flat knitting systems. These technologies enable us to produce a diverse range of fabrics, from lightweight jerseys to intricate textured knits, catering to various fashion needs.

Sustainability is knitted into every stitch. We prioritize ecofriendly practices by utilizing organic and recycled fibers, minimizing waste through precise production techniques, and optimizing energy consumption. Our commitment ensures that each fabric not only feels good but also aligns with our responsibility to the planet.

Our knitting division is capable of producing a wide spectrum of fabrications tailored to both fashion and performance markets. We specialize in fleece, single jersey, interlock, tricot polyester, rib, and loopback terry, along with elastane blends including spandex and lycra jersey. Our facility is optimized for both lightweight and heavy GSM fabrics, ensuring structural consistency, stretch recovery, and dimensional stability across all constructions. With stringent yarn sourcing protocols and in-line quality checks, we provide buyers with scalable, repeatable quality — ideal for activewear, loungewear, and premium casual collections.

Knitting

Where Innovation Meets Tradition

At W. Brothers Apparel, knitting is more than a manufacturing step—it’s the heart of our craftsmanship. We transform approximately 25 metric tons of yarn into premium knitwear every day. This scale reflects not just our operational efficiency but our dedication to meeting global demand without compromising on quality.

Our knitting facility is equipped with state-of-the-art machinery, including advanced circular knitting machines and computerized flat knitting systems. These technologies enable us to produce a diverse range of fabrics, from lightweight jerseys to intricate textured knits, catering to various fashion needs.

Sustainability is knitted into every stitch. We prioritize ecofriendly practices by utilizing organic and recycled fibers, minimizing waste through precise production techniques, and optimizing energy consumption. Our commitment ensures that each fabric not only feels good but also aligns with our responsibility to the planet.

Our knitting division is capable of producing a wide spectrum of fabrications tailored to both fashion and performance markets. We specialize in fleece, single jersey, interlock, tricot polyester, rib, and loopback terry, along with elastane blends including spandex and lycra jersey. Our facility is optimized for both lightweight and heavy GSM fabrics, ensuring structural consistency, stretch recovery, and dimensional stability across all constructions. With stringent yarn sourcing protocols and in-line quality checks, we provide buyers with scalable, repeatable quality — ideal for activewear, loungewear, and premium casual collections.

DYEING

PRECISION AND RESPONSIBILITY

At W.Brothers Apparel, dyeing is a meticulous art form where color meets conscience. With a daily dyeing capacity of 20 metric tons our commitment to excellence and sustainability.

Our dyeing facility is equipped with cutting-edge machinery, including jet dyeing machines capable of operating at low liquor ratios, significantly reducing water and energy consumption. We have integrated digital textile dyeing technologies, which offer cleaner, more sustainable alternatives to traditional methods, minimizing wastewater and chemical usage .

Embracing innovation, we are exploring nanocellulose-based dyeing technologies, which use one-tenth of the water compared to conventional techniques and eliminate the need for toxic chemicals. Additionally, we are investigating supercritical CO₂ dyeing methods, a waterless dyeing process that reduces waste, energy usage, and CO₂ emissions .

Our commitment to sustainability extends beyond technology. By integrating ecofriendly dyeing techniques, we strive to reduce our ecological footprint while delivering vibrant, long-lasting colors.

MERCHANDISING

INNOVATION, COLLABORATION & DEVELOPMENT

At W. Brothers Apparel, our Merchandising Department is the creative and operational engine that drives every collection. It’s where ideas are transformed into tangible products—where client visions are translated into fabric swatches, trims, and prototypes. Our dedicated teams leads every stage of product development, from the earliest sketches to the delivery of finished samples, managing timelines and costs with precision

We prioritize continuous innovation through in-house R&D, exploring the latest yarns, finishes, and garment technologies to create collections that inspire both new and existing clients. Whether developing exclusive fabrications or refining core styles, our merchandisers work closely with designers, production teams, and sustainable suppliers to ensure every element aligns with quality, performance, and environmental responsibility.

Our sustainable supply chain for trims, labels, and accessories ensures ethical sourcing, compliance with global standards, and full traceability—so every garment tells a responsible story from fiber to finish. Through proactive collaboration and meticulous planning, our merchandising team bridges creativity and execution, ensuring each product exceeds expectation in both style and substance.

CUTTING

PRECISION ENGINEERED FOR EXCELLENCE

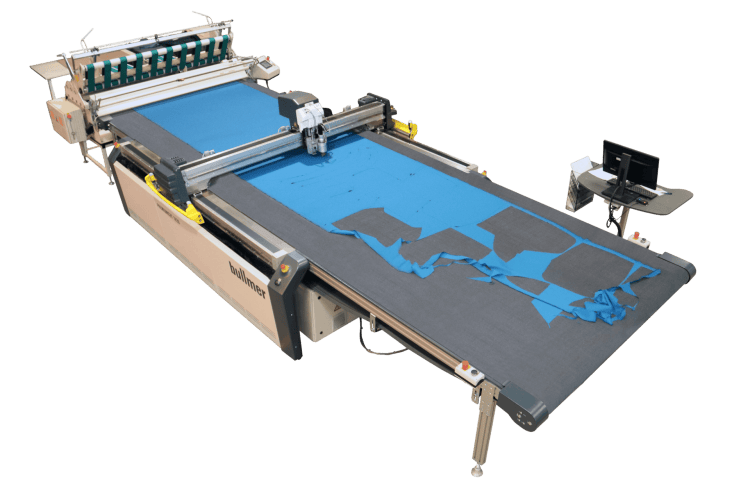

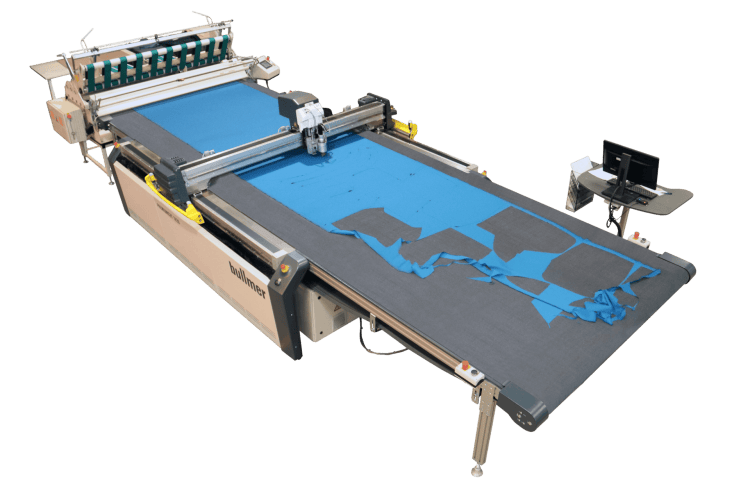

At W. Brothers Apparel, quality begins long before the first cut. Every roll of fabric is first evaluated in our dedicated Fabric Inspection Department, where high-precision inspection machines meticulously scan for defects, ensuring that only flawless materials enter production.

Once approved, the fabric moves to our cutting facility, where over 25 metric tons of fabric are expertly processed each day. Utilizing Gerber Paragon® and Lectra Vector® automated cutting systems, we achieve precise, consistent patterns with exceptional material efficiency.

Yet even in a world of automation, we know that craftsmanship still has a place. For specialty fabrics, complex patterns, or bespoke projects, we complement technology with expert manual cutting by skilled artisans, ensuring unmatched precision where machine lines alone aren’t enough. This thoughtful balance of innovation and human touch reflects our dedication to both quality and detail.

Following cutting, every component undergoes a detailed Cut Part Inspection to verify shape, size, and alignment, ensuring that every piece meets the exacting standards required for flawless assembly. This multi-layered approach guarantees that only the finest materials and workmanship move forward in the journey from fabric to fashion.

At W. Brothers, cutting isn’t just the beginning of a garment’s journey—it’s the foundation of excellence.

STITCHING

EVERY SEAM CRAFTED

At W. Brothers Apparel, stitching is where design transforms into form—where every seam is an expression of craftsmanship. With 35 stitching lines and 1500 machines, operating in a carefully engineered production flow, we achieve the capacity to produce tens of thousands of garments daily without compromising attention to detail.

Each line is designed for optimal efficiency and control, combining automated machinery with expert craftsmanship. Quality isn’t a checkpoint— it’s embedded at every stage. From the first stitch to the last, dedicated quality controllers are stationed at every critical step, inspecting seams, reinforcements, and trims to ensure flawless construction.

Our stitching process balances scale with precision, leveraging standardized workflows while allowing flexibility for complex styles and custom finishes. This harmonious integration of technology, process design, and skilled hands ensures that every garment leaving our line reflects the highest standard of quality, consistency, and care.

QUALITY

EVERY STEP ACCOUNTABLE, EVERY STITCH ASSURED

At W. Brothers Apparel, quality is not a checkpoint—it’s a continuous commitment embedded into every stage of production. Our dedicated quality assurance team follows a multi-layered inspection system, ensuring each garment exceeds expectations before it ever reaches a client.

Our In-Line QA and QC places trained inspectors directly on the sewing line, proactively monitoring every step to catch and correct issues early, safeguarding against defects before they develop. At the completion of stitching, each garment undergoes a thorough End Line QA and QC, verifying every seam, trim, and detail for precision.

Beyond individual checks, we implement Batch Audit QA, randomly reviewing completed lots to detect inconsistencies across larger groups. Finally, every piece passes through a rigorous Final Audit QA prior to packing and shipping—a last safeguard to ensure only garments meeting our highest standard leave our facility. Through this meticulous process, quality is not left to chance; it’s engineered into the very fabric of what we do.

FINISHING

WHERE EVERY DETAIL IS PERFECTED

Finishing is the final touch that transforms a well-made garment into an exceptional one. Our finishing department combines state-of-the-art equipment with experienced craftsmanship to enhance the garment’s appearance, feel, and durability.

Steam tunnels, automated pressing machines, and specialized equipment for trimming, folding, and labeling work together in a carefully choreographed flow, ensuring every garment is professionally pressed, shaped, and prepared for packing. Every fold, button, and label placement is aligned with client specifications, maintaining consistency across thousands of units without sacrificing individuality.

Throughout finishing, quality control remains embedded—inspectors verify that each piece meets aesthetic and functional benchmarks before proceeding to packing. This seamless integration of technology and human oversight ensures every garment leaves us refined, elevated, and truly ready to wear.

PACKING AND SHIPPING

DELIVERED WITH CARE, READY FOR THE WORLD

At W. Brothers Apparel, packing is not just about protection—it’s about presentation. Every garment is folded, tagged, and packed to meet exact client specifications, using eco-friendly packaging materials whenever possible to reflect our commitment to sustainability. Whether destined for boutique displays or global retail chains, each piece is handled with precision to ensure it arrives in impeccable condition.

Before dispatch, every packed order undergoes a final audit, verifying size ratios, quantities, labeling, and packaging compliance. Only after passing this last quality checkpoint does an order proceed to shipping, where our logistics team coordinates timely, reliable delivery across global markets.

From concept to carton, W.Brothers ensures every garment’s journey is marked by care, consistency, and excellence—so that what leaves our doors is worthy of proudly carrying your brand’s name.

Dyeing

Precision and Responsibility

At WBrothers Apparel, dyeing is a meticulous art form where color meets conscience.

With a daily dyeing capacity of 20 metric tons our commitment to excellence and

sustainability.

Our dyeing facility is equipped with cutting-edge machinery, including jet dyeing

machines capable of operating at low liquor ratios, significantly reducing water and

energy consumption. We have integrated digital textile dyeing technologies, which

offer cleaner, more sustainable alternatives to traditional methods, minimizing

wastewater and chemical usage .

Embracing innovation, we are exploring nanocellulose-based dyeing technologies,

which use one-tenth of the water compared to conventional techniques and

eliminate the need for toxic chemicals. Additionally, we are investigating supercritical

CO₂ dyeing methods, a waterless dyeing process that reduces waste, energy usage,

and CO₂ emissions .

Our commitment to sustainability extends beyond technology. By integrating ecofriendly dyeing techniques, we strive to reduce our ecological footprint while

delivering vibrant, long-lasting colors.

02

Introduce

03

Introduce

Fabric Inspection

Precision starts with perfection

We begin every garment with a meticulous inspection process using advanced scanning machines to ensure only flawless fabrics are used.

Cutting

Where accuracy meets efficiency

At W. Brothers Apparel, quality begins long before the first cut. Every roll of fabric is first evaluated in our dedicated Fabric Inspection Department, where high-precision inspection machines meticulously scan for defects, ensuring that only flawless materials enter production.

Once approved, the fabric moves to our cutting facility, where over 25 metric tons of fabric are expertly processed each day. Utilizing Gerber Paragon® and Lectra Vector® automated cutting systems, we achieve precise, consistent patterns with exceptional material efficiency.

Yet even in a world of automation, we know that craftsmanship still has a place. For specialty fabrics, complex patterns, or bespoke projects, we complement technology with expert manual cutting by skilled artisans, ensuring unmatched precision where machine lines alone aren’t enough. This thoughtful balance of innovation and human touch reflects our dedication to both quality and detail. Following cutting, every component undergoes a detailed Cut Part Inspection to verify shape, size, and alignment, ensuring that every piece meets the exacting standards required for flawless assembly. This multi-layered approach guarantees that only the finest materials and workmanship move forward in the journey from fabric to fashion.

At W. Brothers, cutting isn’t just the beginning of a garment’s journey—it’s the foundation of excellence.

04

Introduce

05

Introduce

Stitching

Expert craftsmanship at scale

At W. Brothers Apparel, stitching is where design

transforms into form—where every seam is an

expression of craftsmanship. With 35 stitching

lines and 1500 machines, operating in a carefully

engineered production flow, we achieve the

capacity to produce tens of thousands of

garments daily without compromising attention

to detail.

Each line is designed for optimal efficiency and

control, combining automated machinery with

expert craftsmanship. Quality isn’t a checkpoint—

it’s embedded at every stage. From the first stitch

to the last, dedicated quality controllers are

stationed at every critical step, inspecting seams,

reinforcements, and trims to ensure flawless

construction.

Our stitching process balances scale with

precision, leveraging standardized workflows

while allowing flexibility for complex styles and

custom finishes. This harmonious integration of

technology, process design, and skilled hands

ensures that every garment leaving our line

reflects the highest standard of quality,

consistency, and care.

Finishing

Where Every Detail Is Perfected

Using steam tunnels, automated pressing, folding, and labeling systems, each garment is refined and made retail-ready. QC teams verify aesthetics and structural quality.

06

Introduce

07

Introduce

Quality Control

Tested for perfection

At W. Brothers Apparel, quality is not a checkpoint—it’s a continuous

commitment embedded into every stage of production. Our dedicated

quality assurance team follows a multi-layered inspection system,

ensuring each garment exceeds expectations before it ever reaches a

client.

Our In-Line QA and QC places trained inspectors directly on the sewing

line, proactively monitoring every step to catch and correct issues

early, safeguarding against defects before they develop. At the

completion of stitching, each garment undergoes a thorough End Line

QA and QC, verifying every seam, trim, and detail for precision.

Beyond individual checks, we implement Batch Audit QA, randomly

reviewing completed lots to detect inconsistencies across larger

groups. Finally, every piece passes through a rigorous Final Audit QA

prior to packing and shipping—a last safeguard to ensure only

garments meeting our highest standard leave our facility.

Through this meticulous process, quality is not left to chance; it’s

engineered into the very fabric of what we do.

Packing & Shipping

Ready for the world

At W. Brothers Apparel, packing is not just about protection—it’s about

presentation. Every garment is folded, tagged, and packed to meet exact client

specifications, using eco-friendly packaging materials whenever possible to

reflect our commitment to sustainability. Whether destined for boutique displays or

global retail chains, each piece is handled with precision to ensure it arrives in

impeccable condition.

Before dispatch, every packed order undergoes a final audit, verifying size ratios,

quantities, labeling, and packaging compliance. Only after passing this last

quality checkpoint does an order proceed to shipping, where our logistics team

coordinates timely, reliable delivery across global markets.

From concept to carton, WBrothers ensures every garment’s journey is marked by

care, consistency, and excellence—so that what leaves our doors is worthy of

proudly carrying your brand’s name.